[vc_row][vc_column][vc_column_text]Online shoppers expect to receive their orders quickly, with little-to-no extra cost added throughout the fulfillment process.

There are many ways for e-commerce merchants to decrease fulfillment and delivery times. One area of the supply chain that is often overlooked is the receiving department. Your dock-to-stock times can have a big impact on not only your ability to quickly turn orders, but also on the total cost to get an order to your customer.

Know What You’re Going to Receive, and When

The first step in achieving a well-optimized receiving department is knowing exactly what’s coming into your warehouse, and when.

This may scream obvious, but it happens more often than you know it. A lack of communication can lead to surprise shipments, or warehouses failing to prepare for expected shipments. When either of these occurs, the result is often slower and more costly receiving.

(Source: FinaleInventory)

Here are two examples.

- Warehouse receives more than expected. Let’s say your receiving department expects 5,000 units but eventually 10,000 units arrive – 5,000 more than initially anticipated. Even in a perfect world, it will take twice as long to receive that shipment, or you’ll have to put more staff on the receiving end. Either way, it disrupts your otherwise smooth fulfillment process. This can result in delayed shipments, especially if any of that incoming stock was slated for pending orders. It may also lead to costly overtime, or tie up employees longer than expected, which can create problems in other areas of the operation, and result in a higher per-unit receiving cost.

- Warehouse receives less than expected. If the receiving department receives less stock than it was told, costs could reversely increase due to overstaffing. You may make adjustment for this by reassigning staff or even sending employees home early, although that may lead to inefficiency within other departments, or disgruntled personnel.

What your receiving department expects and what it actually receives (and when) will likely never sync, entirely. However, by communicating closely with suppliers, shipping carriers, and your own receiving department, you can minimize receiving costs and turnaround times.

Standardize the Workflow

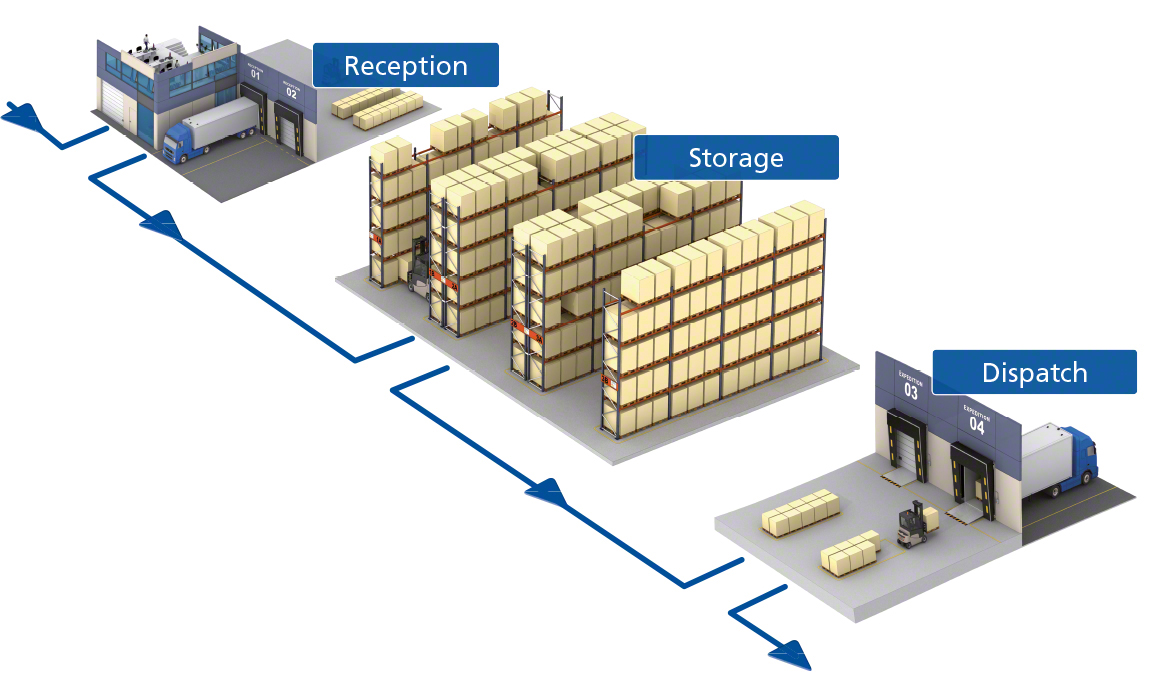

Standardization starts with the design of your receiving department to conform to the type, size, and frequency of the incoming stock. Standardization can lead to increased speed and efficiency, and ultimately reduced costs.

To start standardizing your workflow, consider these questions.

- What is the optimal size for your staging area?

- Does your current flow make sense?

- Does the design minimize the number of steps to the fullest during the receiving process?

- Do receiving stations have all required supplies within an arm’s reach and without any clutter?

- Is the process the same for all shipments, or does it vary?

(Source: Interlakemecalux)

The concept of standardization also applies to the way shipments are organized when they hit your dock.

- Are SKUs individually labeled with product numbers?

- Are master cartons and inner cartons both labeled?

- Are SKUs separated, or are some mixed together within one carton?

- Are all SKUs clearly labeled on a packing list that accompanies the inbound shipment?

Manufacturers will typically prepare shipments in accordance with a retailer’s operation. An added cost might be required of a supplier to do this, although that extra cost could be much less than what the retailer has to pay to its fulfillment vendor, or to its own staff, to organize it all.

Monitor Processing Times

e-Commerce merchants often focus on pick, pack, and shipping costs – the overall fulfillment experience. These are important, but so are receiving costs.

Suppose you pay a receiving employee $12 per hour and that person can typically process 100 units per hour from dock to stock, your receiving cost per unit would be $0.12. If a shipment arrives a disorganized mess and, as a result, the employee’s productivity falls to 30 units/hour, your per-unit receiving cost is now $0.40. For a shipment of 1,000 units, direct receiving costs increase by $280. And that ignores the opportunity cost of spending more time on that receipt, as well as the potential for late shipments if the receiving units contains pending orders.

(Source: Handshake)

Maintaining consistent receiving times with consistent per unit costs is critical for efficiency and profitability. If an incoming shipment significantly deviates from the average, it’s important to dig in immediately and determine the root cause.

It may be that your supplier failed to provide a packing slip, or products were mislabeled. It may be that your shipment arrived later than expected so you had to assign more people (with less experience). Whatever the cause, identify it and resolve it so that it does not occur again.

[vc_separator color=”orange” align=”align_left” style=”dashed”][vc_column_text]BoxMe is the premier cross-border e-Commerce fulfillment network in South East Asia, enabling world-wide merchants to sell online into this region without needing to establish local presence. We are able to deliver our services by aggregating and operating an one-stop value chain of logistic professions including: International shipping, customs clearance, warehousing, connection to local marketplaces, pick and pack, last mile delivery, local payment collection and oversea remittance.

If you have any question about Boxme Asia or how we can support your business, please contact us directly by referring to our hotline. We are glad to be of service![/vc_column_text][/vc_column][/vc_row][vc_column][vc_column_text]

[/vc_column_text][/vc_column][vc_row][vc_column][vc_raw_js]JTNDJTIxLS1IdWJTcG90JTIwQ2FsbC10by1BY3Rpb24lMjBDb2RlJTIwLS0lM0UlM0NzcGFuJTIwY2xhc3MlM0QlMjJocy1jdGEtd3JhcHBlciUyMiUyMGlkJTNEJTIyaHMtY3RhLXdyYXBwZXItNDY1YjMyYWQtNWIzNC00NTQ0LWJhODUtMTg1ZTMyZmZhMmU4JTIyJTNFJTNDc3BhbiUyMGNsYXNzJTNEJTIyaHMtY3RhLW5vZGUlMjBocy1jdGEtNDY1YjMyYWQtNWIzNC00NTQ0LWJhODUtMTg1ZTMyZmZhMmU4JTIyJTIwaWQlM0QlMjJocy1jdGEtNDY1YjMyYWQtNWIzNC00NTQ0LWJhODUtMTg1ZTMyZmZhMmU4JTIyJTNFJTNDJTIxLS0lNUJpZiUyMGx0ZSUyMElFJTIwOCU1RCUzRSUzQ2RpdiUyMGlkJTNEJTIyaHMtY3RhLWllLWVsZW1lbnQlMjIlM0UlM0MlMkZkaXYlM0UlM0MlMjElNUJlbmRpZiU1RC0tJTNFJTNDYSUyMGhyZWYlM0QlMjJodHRwcyUzQSUyRiUyRmN0YS1yZWRpcmVjdC5odWJzcG90LmNvbSUyRmN0YSUyRnJlZGlyZWN0JTJGMjE0MTUyOCUyRjQ2NWIzMmFkLTViMzQtNDU0NC1iYTg1LTE4NWUzMmZmYTJlOCUyMiUyMCUyMHRhcmdldCUzRCUyMl9ibGFuayUyMiUyMCUzRSUzQ2ltZyUyMGNsYXNzJTNEJTIyaHMtY3RhLWltZyUyMiUyMGlkJTNEJTIyaHMtY3RhLWltZy00NjViMzJhZC01YjM0LTQ1NDQtYmE4NS0xODVlMzJmZmEyZTglMjIlMjBzdHlsZSUzRCUyMmJvcmRlci13aWR0aCUzQTBweCUzQiUyMiUyMHNyYyUzRCUyMmh0dHBzJTNBJTJGJTJGbm8tY2FjaGUuaHVic3BvdC5jb20lMkZjdGElMkZkZWZhdWx0JTJGMjE0MTUyOCUyRjQ2NWIzMmFkLTViMzQtNDU0NC1iYTg1LTE4NWUzMmZmYTJlOC5wbmclMjIlMjAlMjBhbHQlM0QlMjJDT05UQUNUJTIwVVMlMjBOT1clMjElMjIlMkYlM0UlM0MlMkZhJTNFJTNDJTJGc3BhbiUzRSUzQ3NjcmlwdCUyMGNoYXJzZXQlM0QlMjJ1dGYtOCUyMiUyMHNyYyUzRCUyMmh0dHBzJTNBJTJGJTJGanMuaHNjdGEubmV0JTJGY3RhJTJGY3VycmVudC5qcyUyMiUzRSUzQyUyRnNjcmlwdCUzRSUzQ3NjcmlwdCUyMHR5cGUlM0QlMjJ0ZXh0JTJGamF2YXNjcmlwdCUyMiUzRSUyMGhic3B0LmN0YS5sb2FkJTI4MjE0MTUyOCUyQyUyMCUyNzQ2NWIzMmFkLTViMzQtNDU0NC1iYTg1LTE4NWUzMmZmYTJlOCUyNyUyQyUyMCU3QiU3RCUyOSUzQiUyMCUzQyUyRnNjcmlwdCUzRSUzQyUyRnNwYW4lM0UlM0MlMjEtLSUyMGVuZCUyMEh1YlNwb3QlMjBDYWxsLXRvLUFjdGlvbiUyMENvZGUlMjAtLSUzRQ==[/vc_raw_js][/vc_column][/vc_row]